Ok so here we go.

Rusty’s old motor was pulled. Fairly easy to do now that I’ve done it a

few times. Drain fluids, disconnect fuel and oil lines, remove radiator,

unplug emissions (injector) harness at the ECU and pull it through, remove intake

filter, AFM, and hose, unplug engine (ignition) harness, unbolt the engine from the

tranny and motor mounts and out it comes. Simple.

First up was getting the injectors cleaned and serviced. These I pulled

off the S5 eBay motor. Due to a compatibility issue with the plug shape

from the 460cc red S4 (‘88) injectors and the emissions harness I had to

use the 460cc red S5 (‘91) injectors. I decided to give WitchHunter a shot.

There were getting good reviews and were cheap - $60 for cleaning, servicing,

and flow testing for all 4 injectors including the return shipping. This included

new pintle caps, new “O” rings, new insulators, and new screens and all injectors

were flow matched. I shipped them on a Monday and had them back the following

Saturday (and this was East coast to West coast!). They looked great. Money

well spent.

After removing the S5 manifolds from the eBay motor they were in dire need

of a good cleaning. A friend ran through their shop steam cleaner and they looked

better afterwards. I also hosed down the inside of the intake runners liberally with

carb and choke cleaner. All the old gasket material was scraped off the three parts

of the intake manifold assembly and I began the task of capping and plugging holes.

First up was installing the ACV block off plate - 3 10mm bolts - done. Next was

the 5/6 port sleeves. Actuators were removed and the studs taken out of the

manifold. I pulled the sleeves out of the lower intake manifold (LIM). NASTY!.

The sleeve actuator shafts in the LIM were jammed in place. The 5/6 ports were not

working on this car for sure. So jammed that when trying to twist them out one

snapped off! Out came the punch and they were hammered out. Similar the shaft

sleeves were hammered out of the LIM also. I then dropped a bolt into each of the two holes and

sealed them in place with some JB weld. Done. The VDI actuator was removed and the VDI

sleeve was wire tied in the open position. Done.

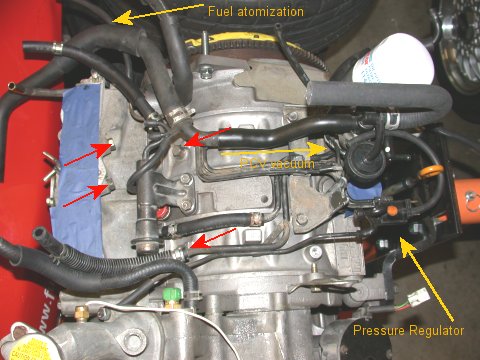

I had planned on simplifying the vacuum system on Rusty but never got to

it. Now with the S5 top end all in pieces and the vacuum spider out lets break

out the dremel and start cutting. Items that can go - 2 solenoids controlling

the ACV (Secondary Air Injection System), 6PI solenoid (6 Port Induction) controlling

the 5/6 port actuators, and the control solenoid working the VDI. The only remaining

solenoid should be the pressure regulator control (PRC) solenoid to assist with hot

starts, and even that is debatable if it’s needed or not. With the 4 extra control

soleniods removed it was just a matter of chasing all the hard lines and removing any

lines that weren’t needed anymore. Any questionable lines were saved and capped and

any unused vacuum sources from the manifold were also capped. The PCV valve and fuel

purge solenoid and lines were left in place. And while I was at it I replaced all the

fuel lines with new hose and did the same for the remaining vacuum lines.

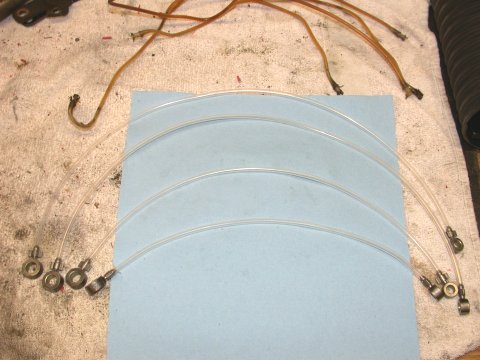

My desire was to maintain a functional oil metering system, but alas it was

not to be. I found this out the hard way. In the beginning I had a set of OMP

lines from the eBay S5 block. A set of broken lines - one line was missing and entire section.

So I would either have to replace the line or...make my own. Discovered on the RX7lcub

forum was an excellent posting on how to make you own lines. I can take NO credit for this

information. But it is good information. All the materials to rebuild the lines can be

sourced from MSC Direct. I ordered:

1) Tubing: MSC # 48701031 available in 10' lengths. 1/8 x 3/16 (CTL)

Teflon PFA - Industrial. Translucent. 1/8" I.D., 3/16" O.D.

$1.51 per foot x 10' = $15.10

PFA Characteristics

• Excellent abrasion & temperature-resistance

• Low coefficient of friction for ease of flow• UV & Gamma radiation stable, chemically inert

• Thermally superior to most plastics

• Outstanding chemical & electrical properties

• Durometer=shore D 55±5

• Temperature range: -320°F to +500°F

2) Clamps: MSC # 48547962. Two-Ear Clamps

Type: 2-Ear, Nominal Size: 1/4, Inner Width of Ear: 0.118 In., Thickness: 0.0276 In., Width: 0.236 In., Material: Stainless Steel

$.33 ea. x 12 = $4.00

So with these materials in hand I did as the originator indicated:

RX7Club Link [note: link may not last]

and made some new lines. I wire-wheeled all the old banjo bolts and fittings and did the same

for the oil injectors themselves. All were cleaned with carb cleaner to degum the insides and

they look almost as good as new. Happy with my new lines and fresh hardware I installed the newly

refurbished OMP system, pump included. Routing the lines without kinking them was a little tricky

as I made them a tad too long but they fit fine. I had originally left the vacuum line nipples

that feed the oil injector nozzles in place during my vacuum spider simplification. With this

taken care of I moved onto the water pump and water pump housing issue.

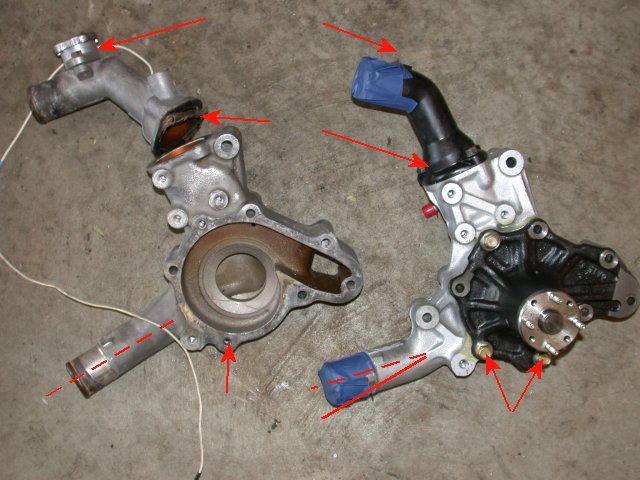

There is a marked difference in the way the cooling system, namely the radiators,

are setup between S4 and S5 cars. In Rusty I have a nice Fluidyne aluminum race radiator....for

an S4. See, on an S4 water pump housing the discharge nozzle feeds to a 2 bolt thermostat

housing. The thermostat having a gasketed flange. And the t’stat housing having a “radiator”

cap at the highest point. The S5 thermostat housing has no radiator cap, as it has been moved

to the radiator, and the t’stat housing is a 3 bolt flange with rubber ‘O” ring instead of a

gasket. Given my S4 radiator does not have the S5 style radiator cap arrangement I needed to maintain

my S4 water pump housing and t’stat housing. No problem...should bolt right up...and it did.

(Be sure to use the shims on the one water pump housing bolt between housing and block -lest you

crack the water pump housing! - the shim is to compensate for the thickness of the gasket on the

other parts of the housing to block interface) This was also good as my S4 t’stat housing is aluminum

and had the fitting for my water temp gauge, the S5 neck is some kind of crap plastic. BUT, two problems arose.

The first being the S4 and S5 water pumps are also different meaning I couldn’t use the brand new

pump that came with the reman motor...damn. All but one of the bolt holes lines up. I’d have to

reuse my old pump. The second problem, and this one really pissed me off, the angle of the lower

radiator return fitting on the water pump housing was different. The S5 is angled up about ˝ inch

to clear the electrical OMP (The S4 has a smaller mechanical OMP).

This meant my S4 housing would not work with the S5 electrical OMP.

The answer, ditch the OMP system altogether and run straight premix fuel like all the other racers. And

all that work refurbishing the OMP lines was for nought. So the OMP was removed and a block of plate

I fabbed up bolted in it’s place, the OMP lines and injectors were removed and bolts installed in

place of the oil injectors (see pic above). It certainly is cleaner looking, the only issue being the OMP has to

remain connected to the electrical harness or else the ECU throws the car into “limp mode.”

SO with all the above done, the upgrades and improvements are complete and all was assembled together. Now

gaskets were used everywhere, new vacuum lines installed, extra vacuum nipples capped, and fuel lines connected.

With the long block essentailly complete the assembly was dropped into the car ready for wiring. ULP!

7-UP CLUB

MAIN

OUR "LOCAL7"

COMMUNITY | THE

WORLD OF THE RX-7

This page last updated June 10, 2006