When last we visited our intrepid racer to be he had just “graduated” from racing school with his race car intact. Since then things have not been so rosey. Lets see what happened.

It was a week later when I had a chance to unload the car off the trailer and move

it into the garage for a few minor repairs. Unfortunately when I started the car to move

it, it was smoking like a mosquito fogger. Smoke so thick it enshrouded my house and most

of the nieghbors as well. “Uh Oh. This isn’t good.” Maybe it’s just leftover oil in the

intake from racing. 15 minutes later...still smoking. So I drive it around the block,

goosing the throttle a bit to clear things out...still smoking. Sad thing is the car is

running fine, making power, started the first time it cranked, it just smokes like crazy.

A check of the mechanical OMP linkage shows all is fine there too. As a last resort I

disconnect the OMP entirely and stick on an blockoff plate. Car idles for a good 20 minutes

to clear out the OMP lines and it’s still smoking....so bad in fact that there is raw oil

DRIPPING out of the exhaust pipe.

The conclusion: running with the single oil cooler in race

traffic, the oil temps must have gotten too high and I fried the oil control rings internal to

the engine. Nothing to do but rebuild the motor. ‘Tis a shame as I had a used motor I was

going to rebuild to use as my spare but never had the chance to rebuild it. Instead now I had

two dead motors on my hands. Oh yeah and the “running” motor I bought off eBay was running on

only ONE rotor, the other having lunched the apex seals. So if you see something from Ben at

IDR Transport (eBay user name: importparts4cheap) beware - he’s not a truthful seller even if

he does have 100% positive feedback.

Now back to my problem. A race car with a toasted motor and strong

desire to go racing. Time to replace/rebuild the motor. Since the motor

had to be rebuilt replaced I decided it was as good a time as any to “upgrade.”

My poor 1988 Series 4 (S4) motor in stock trim made 146hp. The 1989 through 1991

Series 5 (S5) motors in stock trim made 160hp. There are a number of reasons,

lighter higher compression rotors ( http://www.mazdatrix.com/r-rtrwgt.htm ) and

a “tuned” intake tract being the principle reasons. I made the bold decision

that I was going to drop in an S5 motor in lieu of my S4. Well this is not as

simple as it may seem. Many folks rebuild S4 motors with S5 internals and stick

on the S5 intake manifolds to avoid messing with all the electrical issues.

Not me. I’m stupid. I wanted to upgrade the whole enchilada, but for a reason.

The S5 ECU has a higher redline and apparently has better fuel mapping to cope

with the higher redline and better power capabilities. Also noted is the spark

plug hole placement on the S4 housings is not the same as on the S5 housings making

use of an S4 ECU (N32x) with S5 rotor housings not an option. In short, to use

an S5 shortblock, you really should use an S5 ECU (N35x). Enter my original grand

plan. The eBay motor I bought was a longblock complete with all the intake manifolds

and topside ancilliaries. I also bought a 1991 N350 ECU and fuel side “Emissions

Harness.” It was this motor that was originally going to get dropped into Rusty

until it prematurely became a mosquito fogger. I had a decision to make.

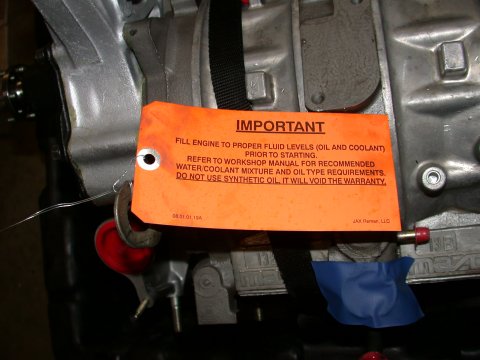

And the decision, although costly, was simply to buy a Mazda factory remanufactured

motor and suck up the cost. I did this for several reasons. 1) Time was of the essence,

i.e., no time to learn how to rebuild a motor and take care of the S4 to S5 conversion;

2) I was assured (hopefully) of parts within spec with the Mazda reman..and a motor that

I know would run (not so sure of my own rebuild) and 3) the kind folks at the dealer

where I bought the reman would allow me to use my S4 motor as a core for the new S5

reman. So, residing in my garage at the time was not one but three motors in various

states of disassembly.

On the list of things to do in preparation for installing the new S5 motor

1) Have the fuel injectors from the S5 eBay motor cleaned, serviced, and flow tested (can’t use the S4 injectors unless you swap connectors - different wiring harness plug)

2) clean up intake manifolds and cap and plug any unnecessary “ports.”

3) remove 5/6 port sleeves and actuators

4) remove double throttle control butterflies from throttle body (see Page http://www.negative-camber.org/crispyrx7/fc/fcpart8.htm) My old S4 TB was not going to work with the S5 electrical due to the difference in the throttle position sensor mounting.

5) simplify the vacuum spider and remove unnecessary control solenoids

6) disable the VDI and lock it in the “open” position

7) swap over the eccentric shaft oil bypass pellet

8) fit S4 water pump housing to S5 block (more on this later)

9) install FD oil pressure regulator and Racing Beat oil pan baffle plate

10) replace the fuel line hoses and all remaining vacuum lines

There’s more but I’ll get into the details later in the following pages.

7-UP CLUB

MAIN

OUR "LOCAL7"

COMMUNITY | THE

WORLD OF THE RX-7

This page last updated June 10, 2006