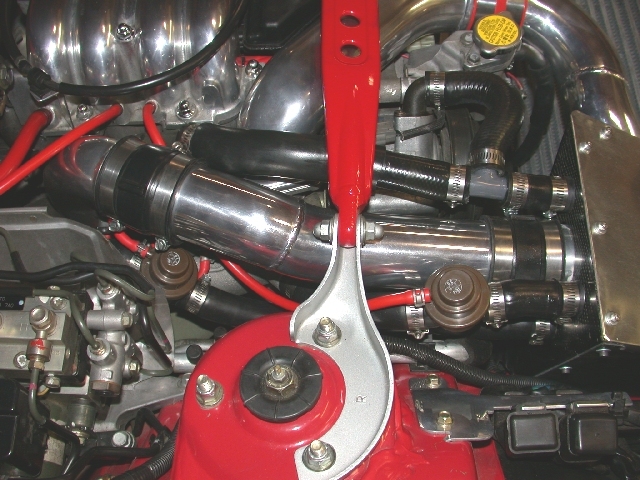

The last piece I needed to complete the install was

this pipe. A very expensive custom fabricated pipe but I think it turned

out well and allowed me to keep the Efini "Y" pipe and not be bothered

with clearance issues associated with the stock air pump. The pipe was

fabricated by Mitch Piper using two 90 degree 2.75" elbows from Burns Stainless.

And there you have it, the finished product of 3 months

of effort.

Another angle

One more.

While I was having the IC inlet pipe fabricated I

thought it might be a good time to have an intake hard pipe made at the

same time. I just had the upper pipe made to replace the stock rubber accordion

as having the lower fabricated would have required completely disassembling

the intake ...again. The pipe was made using a single 2.5" 45 degree elbow.

I decided to stick with the stock rubber connectors as this is a low pressure

relatively low temperature application. Plus the OE connectors look kinda

good in this location... and are inexpensive.

So you have seen my use of the PVC piping elbows as

a *temporary* measure to make the car mobile and enable me to get it to

and from the shop, well this is why it should NEVER be used permenantly!

After driving the car only TWICE and only "boosting" the car ONCE, this

was the net result. Some severely distorted PVC.

Another angle of the PVC piping elbows.

For Day Two of Crispy's install effort

For Day Three of Crispy's install effort

For Day Four of Crispy's install effort

For Day Five of Crispy's install effort