Crooked Willow Racing Intercooler Install Status

More Progress: Day Two

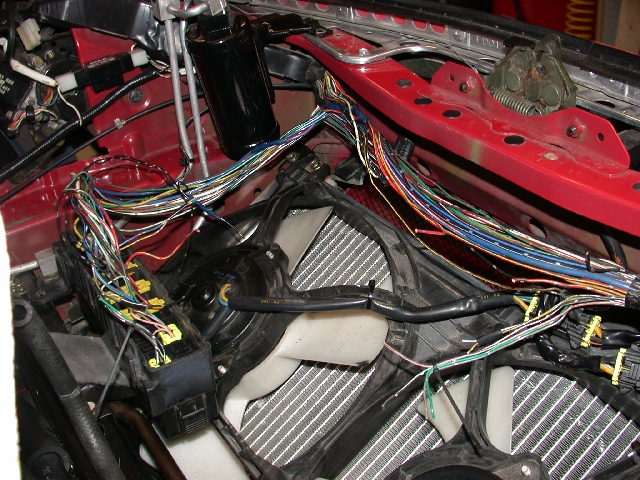

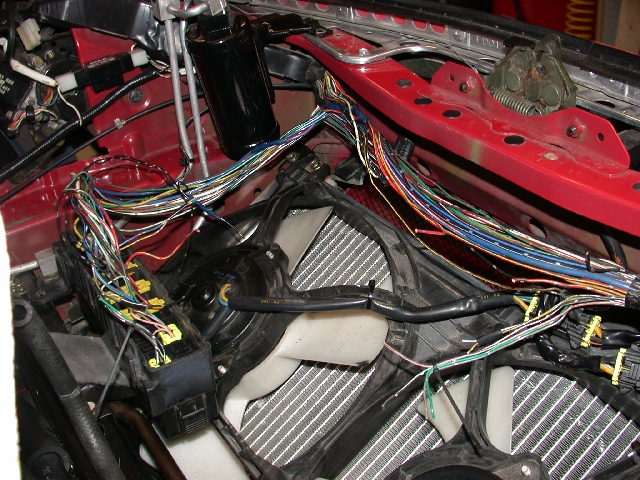

Oh God What have I done! This is one of those times

when there is no other thing to do but to just DO IT! So there I stood

with wire cutters in hand for 15 minutes contemplating what i was about

to do: attempt to relocate the forward relay box without totally buggering

up my car. Now I know it could be done as others had done this before me

but it was still very intimidating. An hour later with the wiring loom

untaped, the wires removed from the plastic wiring tray, and separated

I CUT THE WIRES! Actually there was only few that needed to be lengthened

thankfully. No turning back now though.

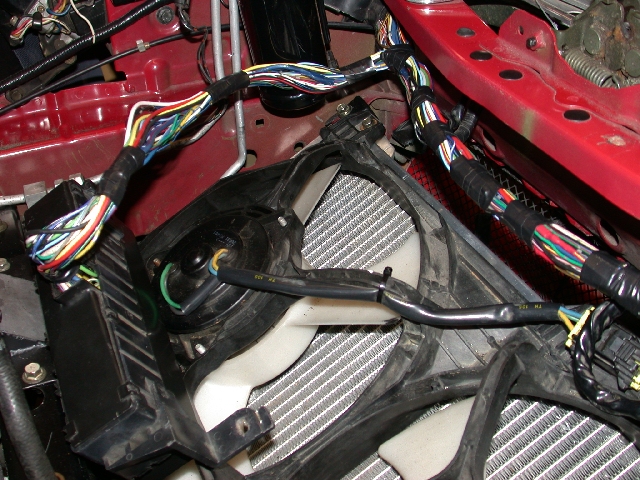

The wires were very well packaged using several plastic

trays and loom covers. Shown are the various wiring trays and other stuff.

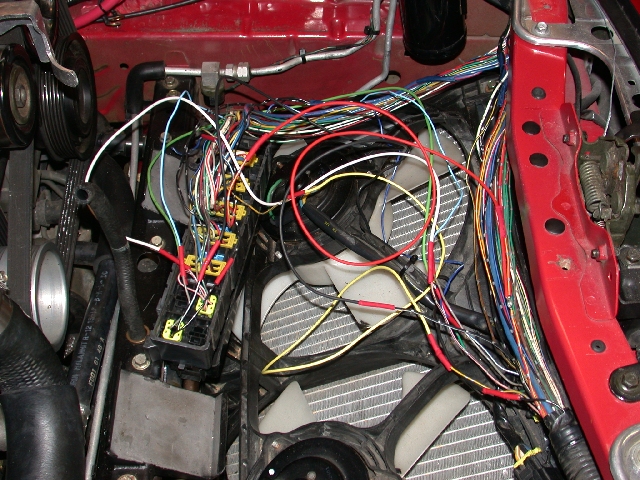

Boy what a mess. I spliced in the extra lengths of

wire using wire comparable in color and gauge to what I was extending.

Each junction was carefully soldered and sealed...in fact probably better

that the OE crimped splices I saw elsewhere when uncovering the wires.

Thankfully none of the wires that needed extending were shielded wires.

In all 9 wires needed extending. Time: 2 hours

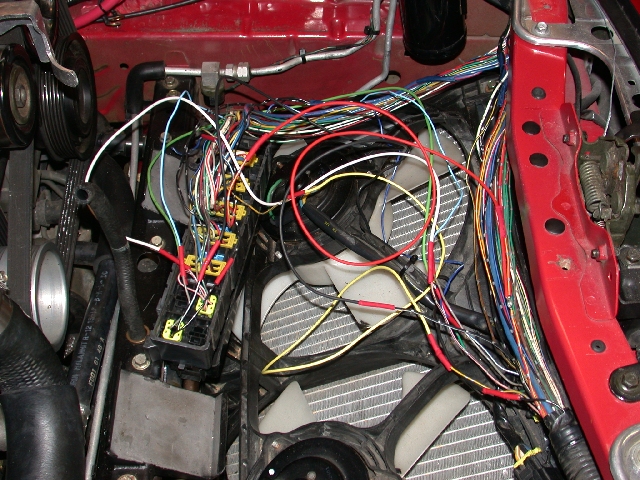

The rebundled wiring with wiring extension allowing

relocation of relay box. The splices were done in locations were the wires

would not be bent and were well protected like inside the underneath of

the relay box.

My effort to wrap the extended wiring harness to the

same level as the OE wrap.

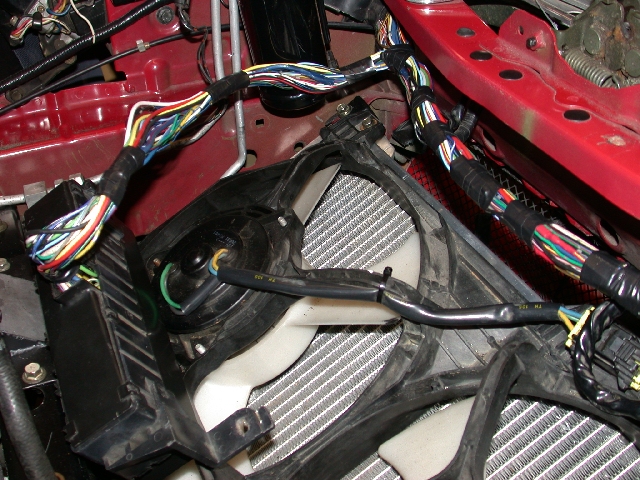

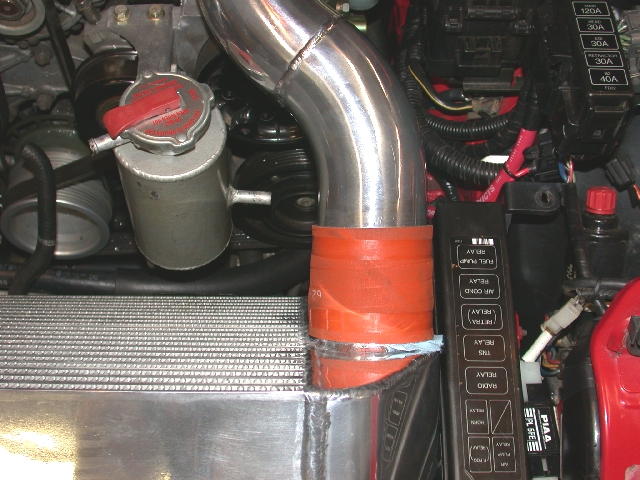

And finally the relay box in it's new home. Brackets

and hold-downs were yet to be fabricated at this time. The relay box was

eventually affixed to the chassis with a bracket on the further end and

a large single zip tie running through the relay box on the closer end.

The PIAA relay was relocated lower to allow the relay box to be positioned

flush with the chassis to the right.

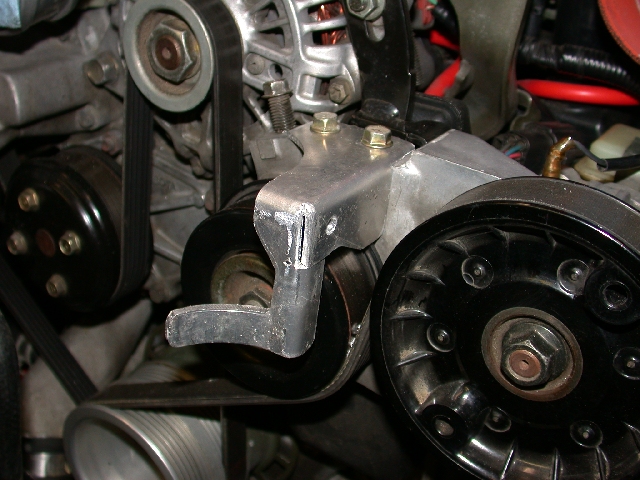

And then there was the AST. What to do with the AST?

Some will say it's unnecessary but I was/am determined to keep it. The

merits of the argument to eliminate it are questionable IMO so if I could

figure out a way to retain the AST I was going to do it. Behold the results

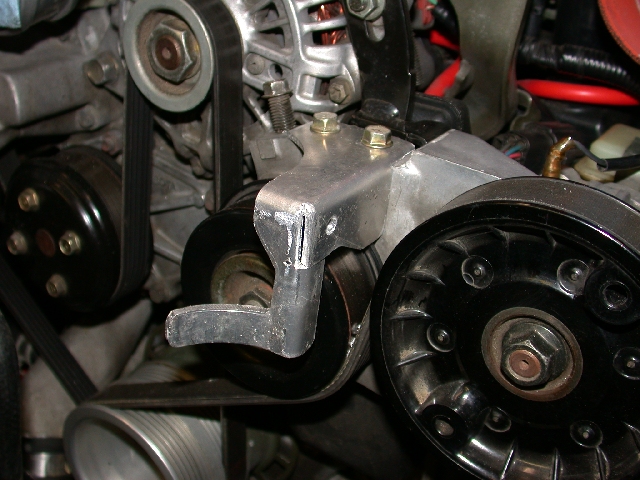

of my effort. And unfinished fabricated AST bracket fashioned from a single

flat piece of aluminum.

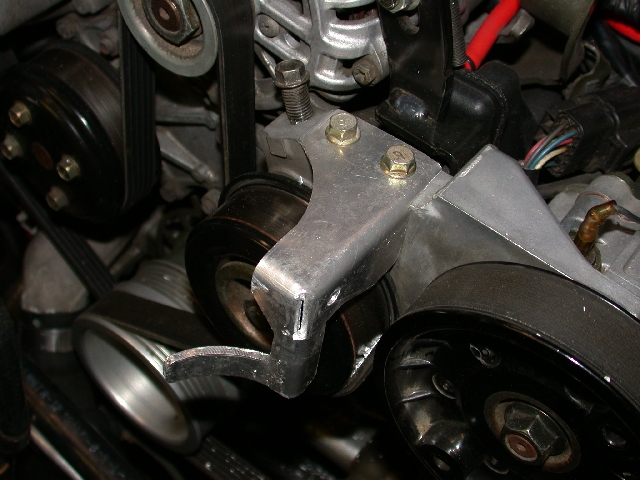

I determined that the power steering pump bracket

had a nice thick, solid, flange along the top surface most suitable for

drilling and tapping. The mount is very solid and does not interfere with

anything in this location.

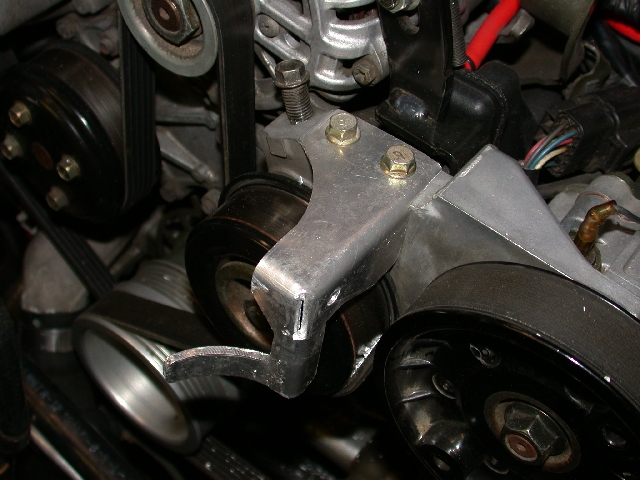

Another angle. The lower arm I felt necessary to prevent

the AST from rotating into the belts if jarred enough or if the mounting

nut works loose over time.

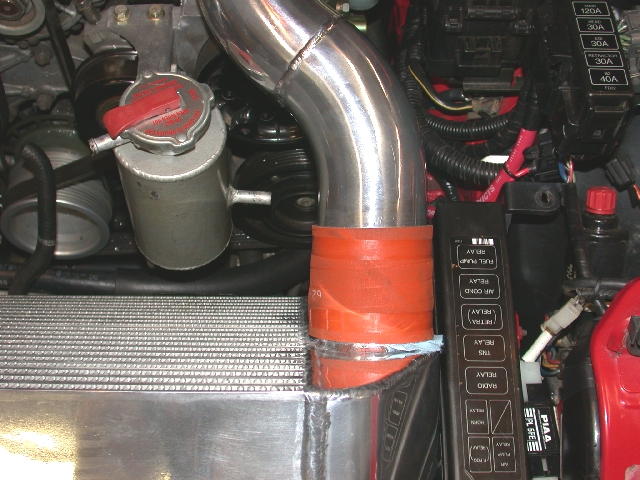

And in summary the fruits of my labor, a newly relocated

relay box and a custom mounted AST.

For

Day One of the CWR install effort

For

Day Three of the CWR install effort

For

Day Four of the CWR install effort

For

Day Five of the CWR install effort

For

Day Six of the CWR install effort

TRIPLE-R MAIN PAGE

GENERAL OVERVIEW |

THE HEART OF THE BEAST |

STOPPING AND TURNING |

THE COMFORT ZONE

7-UP CLUB MAIN

OUR "LOCAL7" COMMUNITY |

THE WORLD OF THE RX-7

If you would like to contact me and converse about my experiences

with my 7:

please feel free to send an e-mail to rotarypower@rx-7.net

This page last updated March 27, 2002

Disclaimer: All images contained on this page are

the sole property of C. Regan